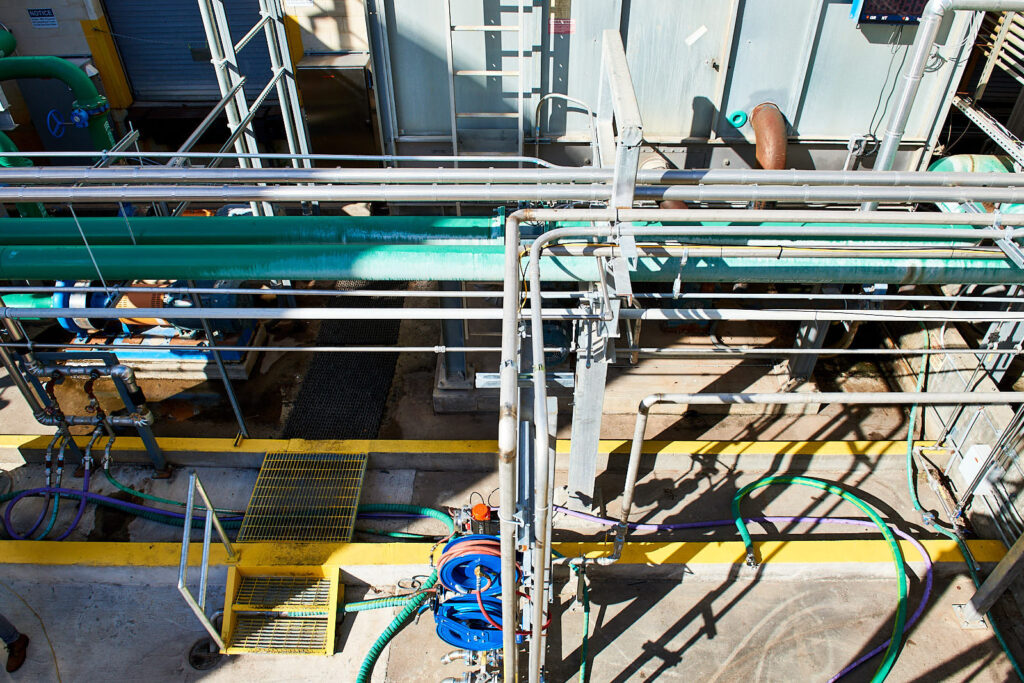

Through careful planning and extensive preparation, MFG Chemical has developed a manufacturing system that allows maximum flexibility and adaptability. Our equipment can adjust to many different customer needs and chemistries. If you have a project that needs help in development support or just a place to have a requirement to manufacture a chemistry already in production, we can tailor-make a solution for your organization. Our manufacturing plants are prepared to assist your business needs and ensure your product is delivered on time and to your specifications.

Through our vast array of knowledge and experience, MFG Chemical can assist you in producing a wide range of chemistries. Our world-class chemists and lab equipment can help you develop a product from ideation to production following your strict specifications. Our expert Quality Control chemists ensure your product is made correctly every time.

Bring our expertise to your business. Let’s build valuable bonds together.